We provide complete granulation line solutions designed for efficiency, flexibility, and seamless integration. Whether you require vertical or horizontal product flow, our systems are tailored to meet your specific process needs. We deliver end‑to‑end solutions for both batch and continuous production, covering processes from granulation and drying to coating and final finishing. With capacities ranging from 500 g to 1,500 kg, our lines are available in 2‑BAR and 12‑BAR pressure‑shock‑resistant constructions, ensuring safety, scalability, and consistent performance

anish traditional granulation line

Our traditional granulation lines follow an open‑loop product transfer approach, making them a cost‑effective solution for standard granulation processes. They are reliable, simple to operate, and ideal for facilities focusing on conventional batch‑based production.

| Model | AGL-Lab | AGL-Pilot | AGL-150 | AGL-300 | AGL-400 | AGL-600 | AGL-800 | AGL-1000 | AGL-1200 | AGL-1500 | AGL-2000 | AGL-2500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | 300gm to 5kg | 2.5kg to 50kg | 30kg to 60kg | 60kg to 120kg | 75kg to 150kg | 120kg to 250kg | 150kg to 300kg | 200kg to 400kg | 250kg to 500kg | 300kg to 600kg | 400lg to 800kg | 500kg to 1000kg |

anish modern granulation line

Designed for advanced manufacturing needs, our modern granulation lines feature closed‑loop product transfer to enhance safety, cleanliness, and containment. This configuration reduces manual handling and ensures compliance with stringent quality and regulatory requirements.

| Model | AGL-Lab | AGL-Pilot | AGL-150 | AGL-300 | AGL-400 | AGL-600 | AGL-800 | AGL-1000 | AGL-1200 | AGL-1500 | AGL-2000 | AGL-2500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | 300gm to 5kg | 2.5kg to 50kg | 30kg to 60kg | 60kg to 120kg | 75kg to 150kg | 120kg to 250kg | 150kg to 300kg | 200kg to 400kg | 250kg to 500kg | 300kg to 600kg | 400kg to 800kg | 500kg to 1000kg |

anish smart granulation line

Our smart granulation lines are custom‑built solutions delivering up to 4X higher output compared to traditional setups. Equipped with automation and process optimization features, they significantly improve productivity, reduce processing time, and enable intelligent manufacturing.

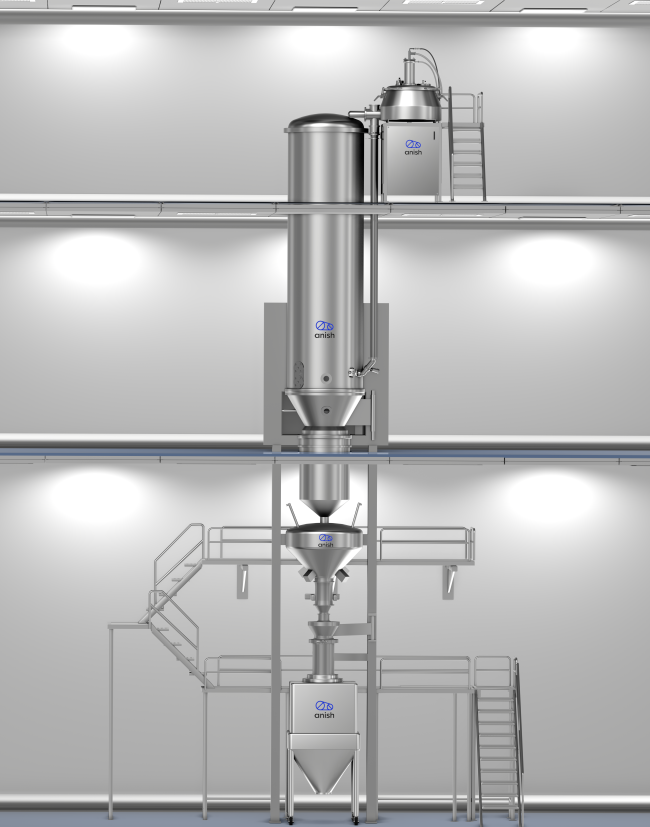

anish vertical granulation line

The vertical granulation line is a customized solution engineered for fast, closed‑loop product transfer. Its compact, vertically aligned design minimizes transfer losses, optimizes space utilization, and enhances overall process efficiency.

FAQs

+

Can customers conduct granulation trials before purchasing the equipment?

+

Is the Anish Granulation Line suitable for USFDA and EU regulated products?

+

Is the Anish Granulation Line scalable from lab to commercial production?

+

Is DQ, IQ, OQ & PQ documentation available for the Granulation Line?

+

How easy is cleaning and product changeover?

+

Does Anish provide service support and spare parts for the Granulation Line?

+

Is the Anish Granulation Lines suitable for potent or containment-sensitive products?

+

Can Anish granulation lines have closed-loop product transfer systems for wet and dry mass transfer?

+

Is Granulation Equipment available in 2 BAR and 12 BAR versions?

Enquiry Form

Request a callback. Interested in knowing more about Anish? Help us with your details & we will get back to you in 48 hours.