Innovation is always the outcome of thought leadership, and often combines diverse fields to take technology to new heights. In the world of Pharmaceutics, one such innovation is Pellets Formulations – the result of a happy marriage between formulation knowledge, and engineering. Pellet Formulation is indeed one of the best technologies, which has vastly improved the administration of solid oral dosage.

Our primary focus will be on the Drug Layering Process, the starting point, and the heart of Pellets Formulations. This process relates to the protective or functional layer, which is crucial in determining the end result of the formulation. There are various Drug Layering Processes, so let’s review each to better understand their merits and demerits.

Methods of Drug Layering

- Powder Layering

- Solution Layering

- Suspension Layering

- Hot Melt Technology

- Coacervation Technology

Powder Layering

Powder Layering wins hands down when it comes to speed in the drug layering process. Traditionally, a coating pan was employed for loading starter pellets, and a suitable binder or polymer was used for drug layering. However, a promising innovation in this area is the Spheronizer, which adds excellent velocity to the Powder Layering Process. This is why there is a growing trend towards commercially employing this wonder equipment.

A good place to check this out is Anish Pharma, a forerunner in Pharmaceutics technology. The Anish Spheronizer impeccably converts the extrudate (output from extruder machine) into uniform and consistent small rounded or spherical pellets.

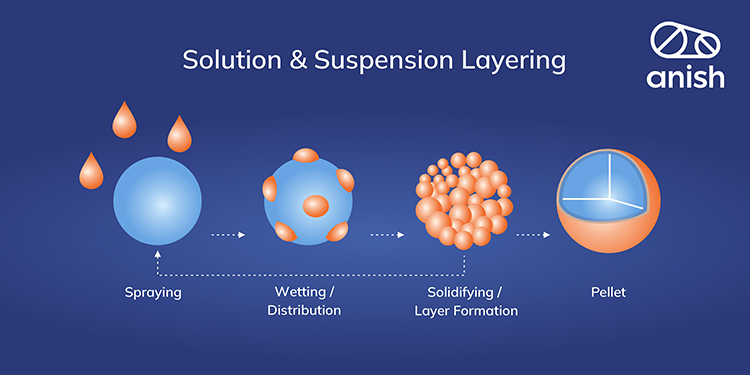

Solution Layering

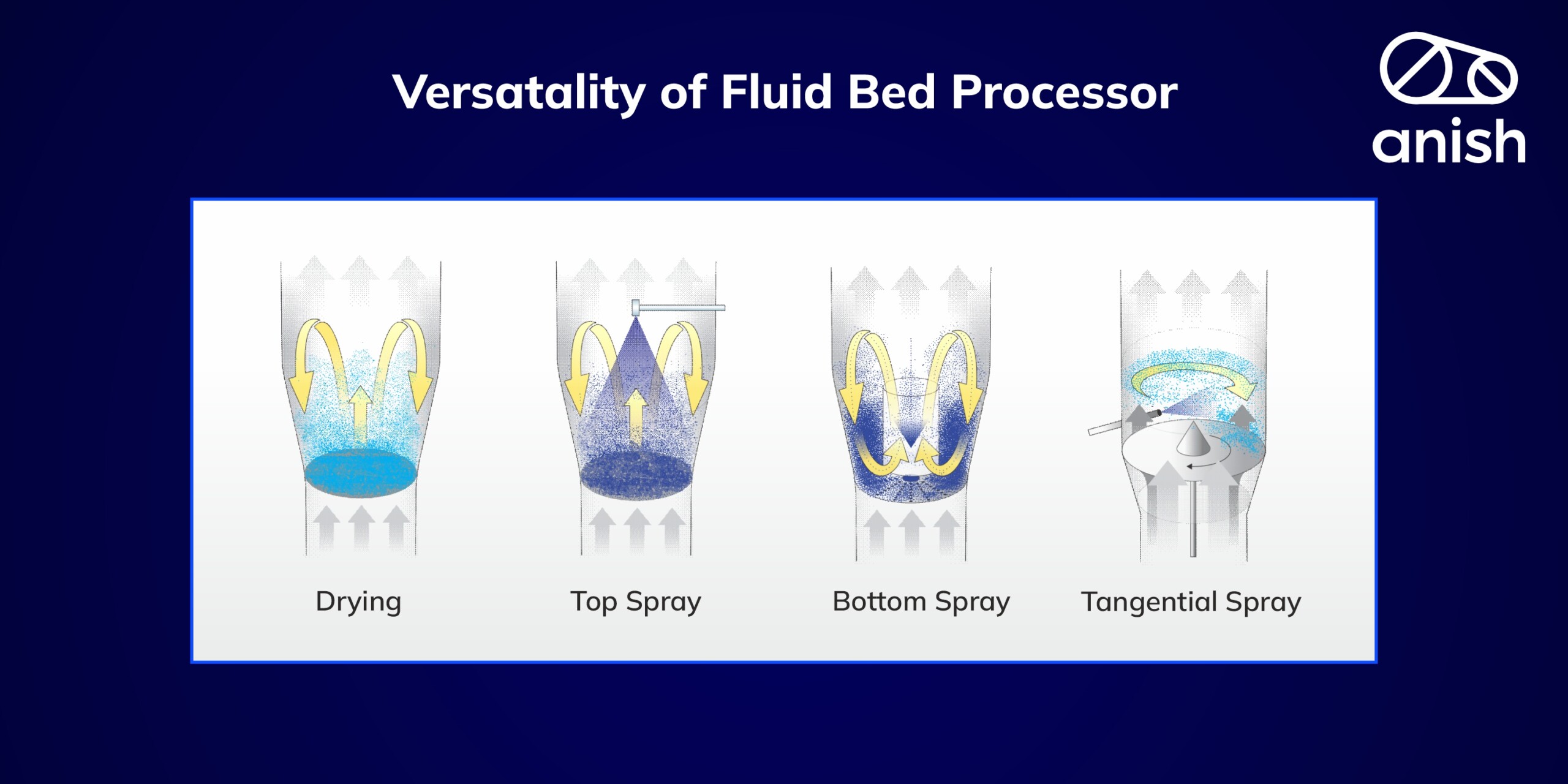

This process uses Fluid Bed Technology for drug layering. A base solvent like water or an organic solvent is used to dissolve the drug that has to be layered, and this is then sprayed on the starter pellets using an appropriate polymer as a binder. Fluid Bed Technology comes in two forms – Bottom Spray (Wurster process) and Tangential Spray. The latter form has fewer takers because the yield loss is higher than the Bottom Spray Fluid Bed Technology. However, Solution Layering is expensive, and it is not suitable for APIs (Active Pharmaceutical Ingredients) with low solubility or if non-soluble in the appropriate solvents.

A word of caution: Organic solvents have long-term carcinogenic effects, so their usage is a red flag that must be avoided.

Suspension Layering

Suspension Layering uses the Bottom Spray (Wurster process) Fluid Bed Technology. The solid substance is dispersed in water, together with a suitable binder, and sprayed on the starter pellets using the Bottom Spray Fluid Bed Processor. This is the most popular drug layering technology, and it is a combination of Powder Layering and Solution Layering Technologies. In terms of speed, it is slower than Powder Layering, but faster than Solution Layering. The particles emitted under this process have a smoother surface and are homogenous in particle size distribution vis-à-vis Powder Layering. This gains significant relevance because the industry standard recommends that the particle size of APIs should be below 50 microns. Smaller particle sizes enable formulators to control the drug’s dissolution and bioavailability accurately.

To know more about the extensive range of customisable Fluidized Bed Processors, get in touch with Anish Pharma Pvt. Ltd. Anish Fluid Bed Processors are replete with SCADA 21 CFR part-11 compliance, and concur with international manufacturing standards.

Hot Melt Technology & Coacervation Technology

These two technologies have more academic and theoretical significance than industry practicality hence they are seldom used in drug manufacturing.

Visit www.anishpharma.com for in-depth information on a range of Fluid Bed Processors, Spheronizers, and the whole gamut of advanced equipment for Pharmaceutics. Anish Pharma’s thought leadership has made it a name to reckon with, as an end-to-end process solutions provider for Granulation and Pelletisation, catering to Pharma, Nutra and Food industries. With more than 32 years of global expertise, Anish Pharma is a trusted name in the Pharmaceutical industry – a name you can consistently count on.

Search

Search